The Advancements in 3D Printing Technology

3D Printing Technology, also known as additive manufacturing, has been around for decades, but recent advancements have made it more accessible and versatile than ever before. From creating prosthetic limbs to printing entire houses, the possibilities of 3D printing are endless. In this article, we will delve into the recent advancements in 3D printing technology and how they are shaping the future of manufacturing.

Materials:

One of the biggest advancements in 3D printing technology is the increasing variety of materials that can be used. In the past, most 3D printers were limited to using plastics and resins, but now, they can print with metal, ceramics, and even biological materials. This expanded range of materials allows for the creation of stronger, more durable, and more complex parts and products.

Speed and Precision:

Another major advancement in 3D printing technology is the increase in speed and precision. With new printing methods and improved hardware, 3D printers can now produce parts and products faster and with greater accuracy than ever before. This allows for more efficient and cost-effective manufacturing processes, as well as the creation of parts and products with finer details and more intricate designs.

Multi-Material Printing:

Multi-material printing is another advancement that has greatly expanded the capabilities of 3D printing. With this technology, multiple materials can be used in the same print, allowing for the creation of parts and products with unique properties and functions. For example, a part could be printed with a hard plastic exterior and a soft rubber interior, or with a metal frame and a plastic cover. This allows for greater flexibility in design and functionality.

Large Scale Printing:

While 3D printing has traditionally been used for small-scale projects and prototypes, recent advancements have made it possible to print on a much larger scale. This includes the development of large-scale 3D printers and the use of robotic arms to print entire structures. This technology is being used to create everything from houses and bridges to entire skyscrapers.

Desktop 3D Printing:

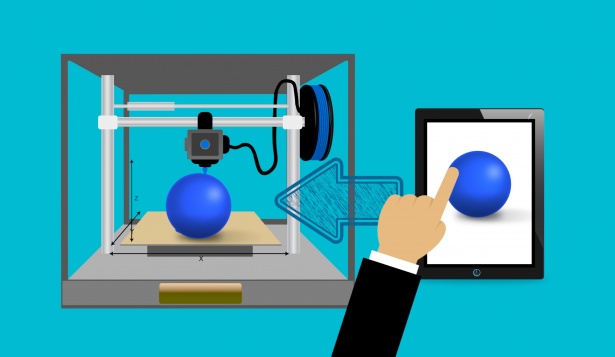

The development of desktop 3D printers has made the technology more accessible and affordable for individuals and small businesses. These printers are smaller and less expensive than industrial-grade printers and can be used to create a wide range of objects.

Decentralized Manufacturing:

With the advancements in 3D printing technology, the concept of decentralized manufacturing is becoming a reality. This means that instead of having to rely on centralized manufacturing facilities, individuals and small businesses can now have their own 3D printers and produce their own products. This not only allows for more local and sustainable production but also empowers individuals and small businesses to be more self-sufficient and competitive in the global market.

Customization and Personalization – 3D Printing Technology:

3D printing technology also allows for greater customization and personalization of products. With the ability to easily create unique designs and models, individuals and businesses can now produce products that are tailored to their specific needs and preferences. This is particularly useful for industries such as fashion, jewelry, and accessories, where customers are looking for unique and personalized items.

Medical Applications – 3D Printing Technology:

3D printing technology has also had a significant impact on the medical field. With the ability to create customized prosthetic limbs, implants, and surgical tools, 3D printing is revolutionizing the way medical devices are manufactured. It has also been used to create 3D-printed organs and tissue, which has the potential to greatly improve transplantation and regenerative medicine.

Environmental Impact – 3D Printing Technology:

3D printing technology has the potential to greatly reduce the environmental impact of manufacturing. With the ability to produce products locally and on demand, it reduces the need for transportation and storage of products. Additionally, 3D printing can also reduce the amount of waste generated during the production process, as it allows for the creation of products with minimal material waste.

Challenges and Limitations – 3D Printing Technology:

Despite the many advancements in 3D printing technology, there are still challenges and limitations that need to be addressed. One major challenge is the cost of 3D printers and materials, which can still be prohibitively expensive for many individuals and small businesses. Additionally, while 3D printing can produce highly detailed and complex parts and products, it can still be difficult to achieve the same level of precision and finish as traditional manufacturing methods.

Advancements in Software – 3D Printing Technology:

There have been significant advancements in the software that is used to create 3D models and control 3D printers. This has made the process of 3D printing more user-friendly and has allowed for the creation of more complex and detailed objects.

These advancements in 3D printing technology are just the beginning, and it is expected that the technology will continue to evolve and improve in the future. As 3D printing becomes more widely adopted, it has the potential to revolutionize various industries, including manufacturing, healthcare, and architecture.

Conclusion:

3D printing technology has come a long way and has the potential to greatly impact the future of manufacturing. It has the ability to empower individuals and small businesses, revolutionize the medical field, and reduce environmental impact. The advancements in 3D printing technology are numerous and have the potential to revolutionize various industries. From the development of new and improved materials to the increase in speed and precision, 3D printing technology has come a long way in recent years. The ability to print with multiple materials, the accessibility and affordability of desktop 3D printers, and the advancements in software have made 3D printing more accessible and user-friendly. With ongoing research and development, it is expected that the technology will continue to evolve and improve in the future. As 3D printing becomes more widely adopted, it has the potential to transform industries such as manufacturing, healthcare, and architecture. However, it is important to acknowledge that challenges and limitations still exist and continue to evolve as technology progresses.

2 thoughts on “The Advancements in 3D Printing Technology”